BLOG

You probably know that indoor air quality is often worse than outdoors. The installation of sensors to monitor IAQ is therefore recommended in order to identify the different pollutants present in a building, their concentration and their source of emission.

They thus make it possible to implement actions to prevent indoor pollution peaks and ensure both the comfort and health of users.

The data collected by these air quality sensors is an integral part of the intelligence of our INDALO® Supervision solution. Our R&D department compared different microsensors to evaluate their reliability, repeatability and performance.

| Note: Repeatability refers to the ability of a sensor to provide multiple similar results from the same observation. It is therefore a question of assessing the coherence between different measures.

Air quality sensors, also known as micro-sensors, are devices designed to measure and evaluate various parameters related to air pollution. They provide accurate data on the environment in which they are placed.

These devices allow a wide variety of measurements to be collected:

Suitable for outdoor or indoor use depending on the models, they can be installed in all types of places such as homes, offices, medical practices or public places such as nurseries, schools or museums.

| Note: in some countries, regulations require indoor air quality monitoring in certain establishments receiving visitors.

Depending on the model, these sensors are able to collect a wide variety of data. They therefore present themselves as a relevant tool to improve the health, comfort and energy efficiency parameters of your building.

Indeed, the collected measurements make it possible to identify the concentration and type of pollutants present in your building as well as their emission sources. In this way, it becomes possible to implement measures to reduce or eliminate them and thus improve your indoor air quality.

The measurements collected are also used to feed into monitoring and steering solutions called BMS. These intelligent devices analyze different parameters (temperature, humidity, IAQ…) in order to optimize the operation of a building’s technical installations. Thus, according to the data collected and the equipment in place, a BMS is able to reduce energy consumption, improve the thermal comfort of occupants or ventilate so as to guarantee healthy air.

The installation of sensors is therefore an essential step to improve indoor air quality, energy efficiency and thermal comfort in a building.

Depending on the model, sensors may have some defects. First, there are times when various environmental factors such as humidity or temperature may distort the measurements.

In addition, some pollutants are difficult to quantify, especially in real time, which reduces the ability of sensors to provide a complete and reliable assessment of air quality.

Of course, these shortcomings should not deter you from using sensors. They simply need to be taken into account when implementing an air quality monitoring system to ensure the most reliable and accurate measurements possible.

| Note: it can be difficult to choose from the wide variety of sensor brands and models available on the market. Octopus Lab can assist you in monitoring the indoor air quality of your establishment and in implementing a solution adapted to your problems.

Within our smart solution, INDALO® Supervision, measurements made by air quality sensors and micro-sensors help us to better understand the use of a building.

Once coupled with artificial intelligence, they allow us to adapt our predictions in order to implement the best possible control of HVAC systems (heating, ventilation, air conditioning).

Our R&D department has therefore decided to compare the indoor air quality monitoring of 27 air quality sensors in order to evaluate their repeatability, or the accuracy of the measurements collected.

This study focused in particular on carbon dioxide (CO₂), emitted indoors by the presence of occupants and which is a good indicator of room confinement, as well as nitrogen dioxide (NO₂), a pollutant mainly from outside.

Sensors were installed for 15 days in one of our offices where the air was strongly renewed and stirred to homogenize the concentrations of pollutants within the room.

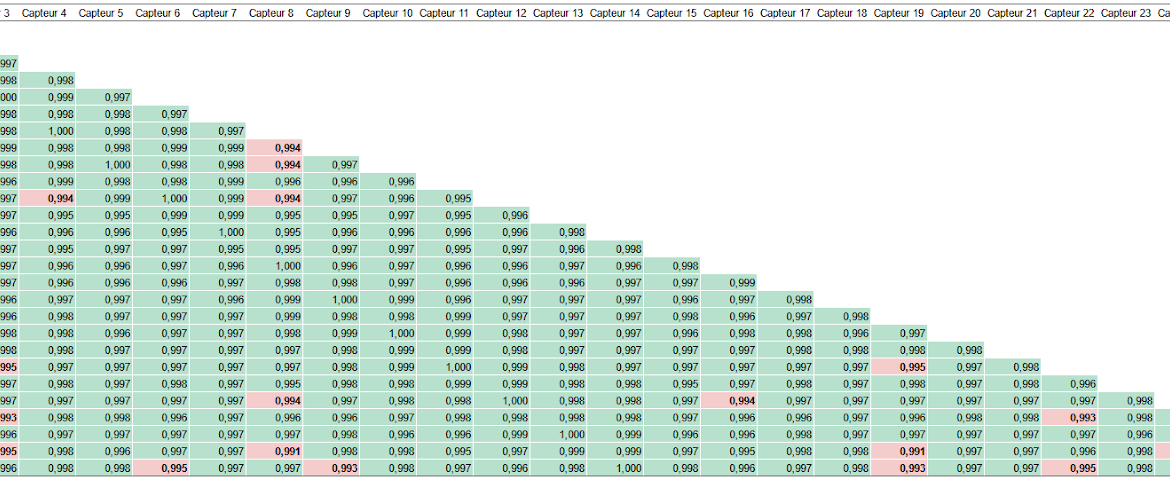

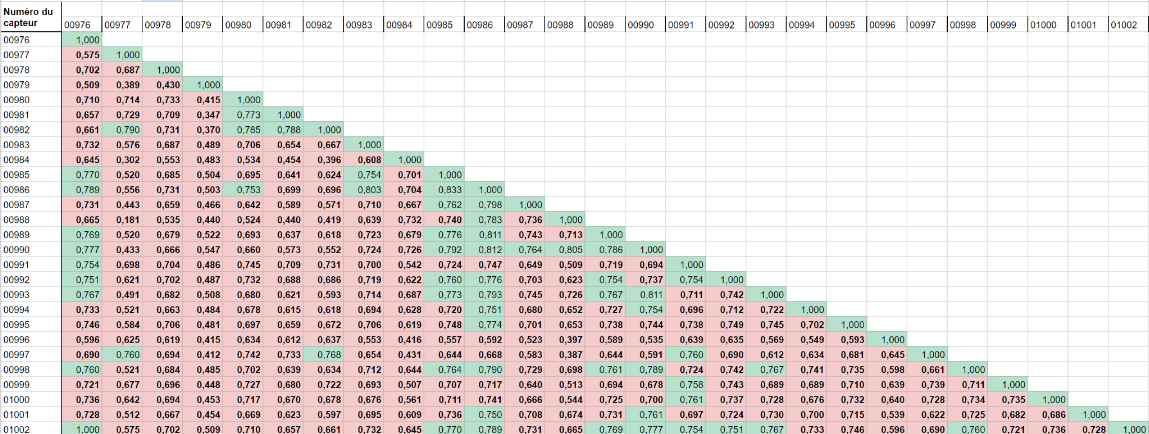

The comparison of sensors revealed that comfort parameters (CO₂, temperature, humidity) were correctly measured. The correlation of CO measurements between different sensors is extremely strong as shown in the graph below, since only 7% of the sensors provide measurements outside the confidence interval.

On the other hand, the study found that some specific pollutants such as NO₂ had a too high signal/noise ratio. This means that the information transmitted to the sensor is interfered with by interference, which deteriorates the quality of the information transmitted.

The analysis of variability then reveals the limits of the sensors since it is observed that in two out of three cases, the NO₂ averages are not within the confidence interval.

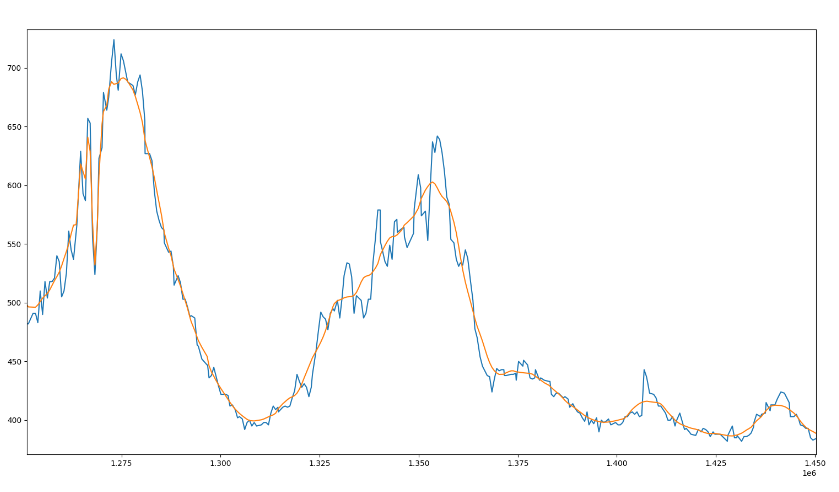

The study reveals that the raw data measured allowed for simple monitoring of air quality, but some pollutants or phenomena were not well reproduced or measured.

To address this issue, we have developed a powerful data processing algorithm integrated with the INDALO® Supervision solution. It removes aberrant data, eliminates noise, retains qualified signal, and detects sensor drift.

It is a unique and registered data processing technology to enhance and improve the processing of your measurements. The information received by the cleaned-up sensors is more accurate and reliable, making it a more effective way to work towards improved indoor air quality.

Bonjour ! C'est nous, les cookies 🍪

Nous sommes chargés de compter le nombre de visites sur ce site internet. Nous aidons énormément les personnes qui travaillent ici, car nous leur permettons d'améliorer le contenu du site internet mais aussi de rendre votre visite plus agréable.